About the project

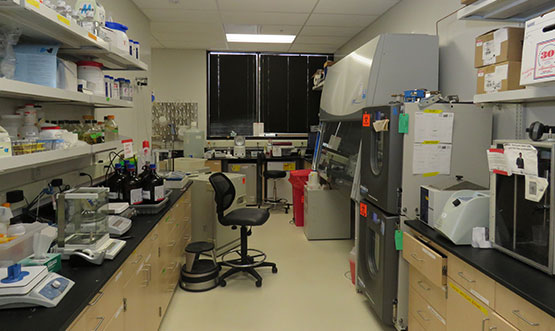

In 2008, AGC provided design-build services for Stanford University to design and install a laboratory in an existing lab building on campus. The lab was approximately 1,600 sqft and consisted of one main lab area with two adjacent laser lab rooms and an adjacent tissue culture room. The laser lab rooms were unique because they had tight temperature control criteria, noise criteria, and low air velocity criteria.

The scope of the project required the installation of new custom air handlers in a tight mezzanine space and custom controls to maintain the required temperature tolerances. Duct silencers were selected that could fit into the available geometry in the mezzanine and still provide the necessary sound reduction. The project also required the typical lab utilities such as natural gas, compressed air, vacuum, DI water, lab sink plumbing, and cylinder gas piping.

After design was completed and the project was under construction, the temperature control criteria for one of the two laser labs was clarified to be even more stringent than the original design. AGC reacted quickly to redesign the system for the new criteria and revised air handling equipment to minimize the project delay.

This project is typical of the many design-build lab retrofit projects that AGC engages in. Each lab project has its own unique set of criteria and needs. AGC excels at working with the final end users to determine those needs and tailor the design to meet all of the requirements. By getting involved early in the design, we are often able to make suggestions to the lab users that improve the final environment they will be working in for years to come.

Address: Address: 745 - B Camden Avenue Campbell, CA 95008

Office: 408-369-6305

Email: randy@agcinc.com